- Requirements for the flywheel plate.

One of the main requirements for the flywheel adapter plate is manufacturing accuracy! The adapter plate must be precisely aligned relative to the engine and transmission axes. Any deviation can lead to vibrations, poor clutch performance, accelerated wear of components, and even transmission failure. The design and dimensions of the plate must exactly match the mounting points of both the engine and transmission. The alignment tolerances can generally be as follows:

1. Alignment axes: For proper operation of the units (engine and transmission), the axes must be aligned with a tolerance no greater than 0.1–0.2 mm. This means the rotation axis of the engine and transmission must be positioned as precisely as possible to avoid additional wear and vibrations.

2. Parallelism: The parallelism between the engine and transmission flanges is also critical, with the allowable gap being around 0.05 mm per 100 mm of length.

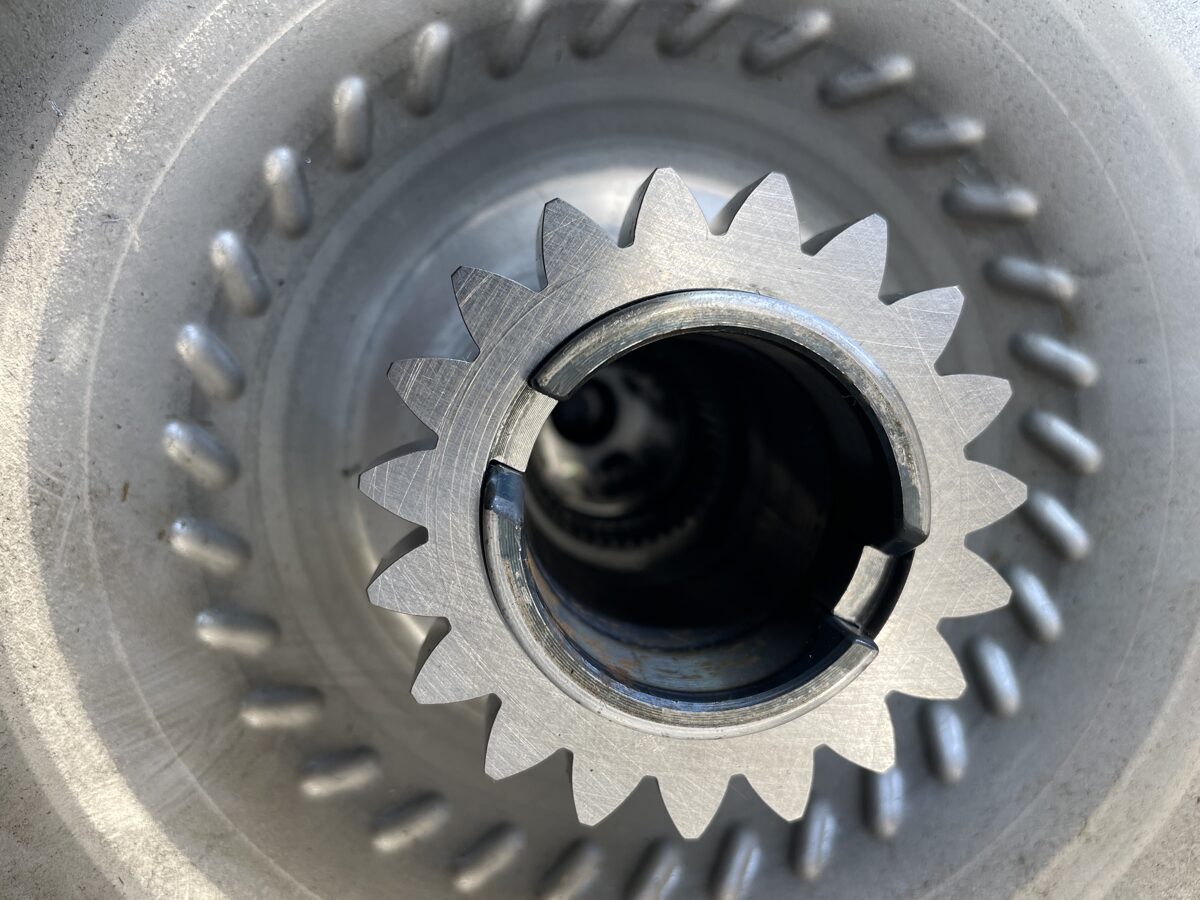

I myself believe that 0.3mm is too much because the fit of the oil pump drive gear on the 7G-Tronic transmission's torque converter shaft is definitely less than 0.3mm! There is no play. And if the end faces of the torque converter gear have parallelism deviation, the gear will rub against the bell housing of the transmission.

It will be supplemented